What We Can Do

At RoslinCT, we understand the importance of designing efficient and reliable manufacturing processes for your cell therapy to achieve clinical and commercial success.

Our comprehensive process development (PD) and analytical development (AD) services are tailored to help you think beyond your current manufacturing needs and create forward-thinking approaches that improve the commercial viability of your products.

RoslinCT PD & AD capabilities support the development, optimization, and translation of novel cell therapy processes into cGMP-compliant drug products that meet phase-appropriate regulatory expectations.

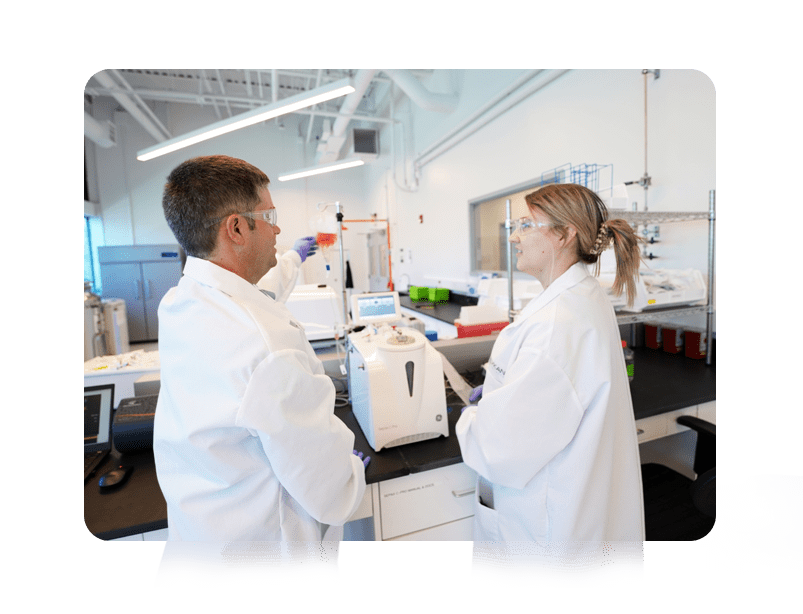

Our team of dedicated cell therapy PD & AD Scientists is available to assist our partners at all stages of development – from lab-scale proof of concept all the way to fully matured, commercially feasible cell therapy products and beyond. Through close collaboration with our partners, our comprehensive approach to PD & AD includes the following key steps:

- Process Gap Analyses: We thoroughly evaluate the commercial- and/or cGMP-readiness of your process and identify gaps that can be addressed to facilitate the advancement of your product.

- Establishment of Critical Process Parameters (CPPs) and Critical Quality Attributes (CQAs)s: We work with you to define the key parameters, attributes, and process windows that are vital to the success of your process.

- Optimization of Unit Operations: We optimize process modules and individual unit operations to reduce handling frequency and operator manipulations while improving overall yield and process costs.

- Process Enhancement: We perform rigorous testing to demonstrate process improvements through scale-up, scale-out, process closure, and automation.

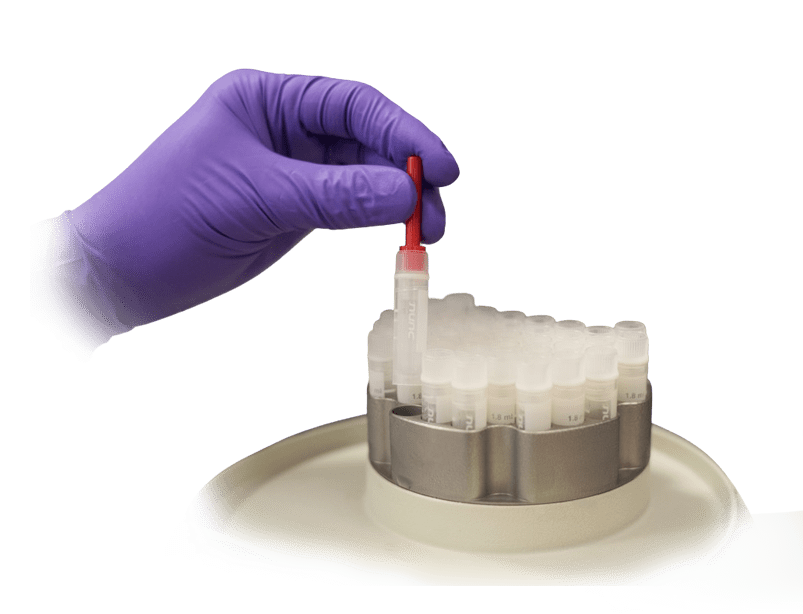

- Drug Product Stability Studies: We design appropriately scaled models to ensure the short- and long-term stability of your drug product.

- Reagent and Product Component Comparability Studies: We conduct comparability studies to ensure that all reagents, product components, and ancillary materials are consistent and meet the required specifications without impacting drug product Safety, Identity, Strength, Purity, or Quality.

- Development of In-Process and Release Analytics: We identify Critical Process Parameters (CPPs) and Critical Quality Attributes (CQAs) that are unique to your process and product.

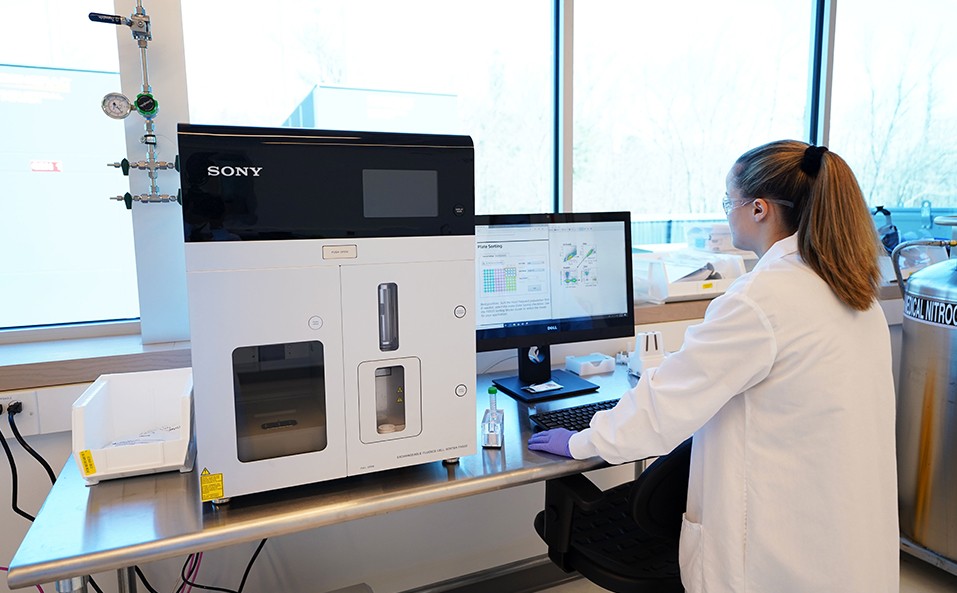

- Method Development and Validation: We can develop and validate analytical methods for your cell therapy product, including cell-based assays, flow cytometry, q/dPCR, ELISA, and more.

Begin with the End in Mind

At RoslinCT, we recognize that the development of a robust and reproducible production process becomes increasingly important as the product advances through clinical trials toward successful commercialization.

We work closely with our partners to optimize their processes and recommend combinations of cell processing instruments and approaches, with the goal of improving product quality, step yields, and reducing manufacturing cycle times.

Our team works to transition open cell handling processes with manual manipulations, into closed, more automated formats as they become available. Automation reduces contamination risks and ensures robustness and reproducibility by reducing operator involvement during cell selection, cell engineering, and cell expansion unit operations.

Partner-Centric Approach

RoslinCT’s team is experienced and well-versed in all aspects of process development and cGMP translation. We advise and support our partners in choosing the most optimal analytical and cell processing platforms.

Team Experience

RoslinCT’s team has decades of biotechnology industry experience with different platforms, tools, and technologies. We support both autologous and allogeneic processes. Our experience includes Pluripotent Stem Cells (iPSC and hESC), T cells (CAR-T, Treg cells), NK cells, Hematopoietic Stem Cells (PBMCs, CD34+), Mesenchymal Stem Cells (MSC), primary tissues (fibroblast and blood processing) and more.

We have experience in viral and non-viral gene delivery and genetic modifications using CRISPR/Cas and innovative technologies.

We also have in-house analytical capabilities including rapid sterility and mycoplasma detection methods, cell counting assays, ELISAs, qPCR/dPCR, flow cytometry, and potency assays.

Process and Analytical Development Innovation Labs

RoslinCT has dedicated laboratory space available for PD/AD. This Innovation Lab is outfitted with state-of-the-art molecular biology and cell therapy processing technologies as well as innovative technologies at the forefront of the field.